|

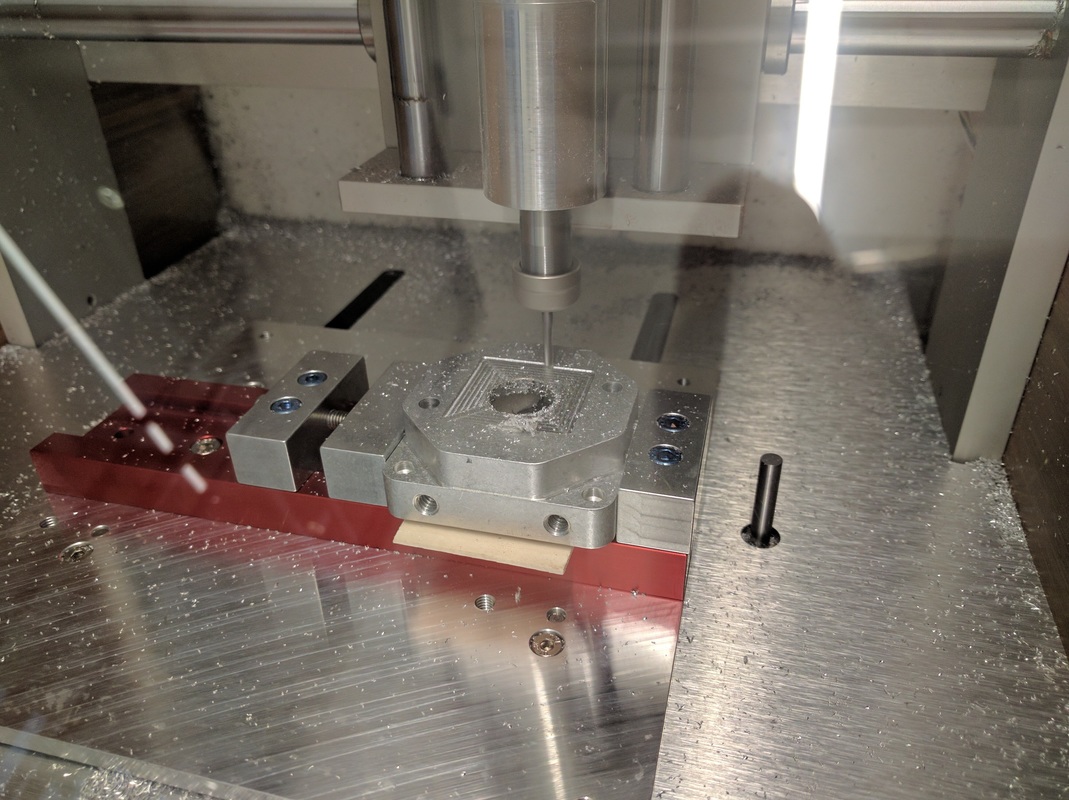

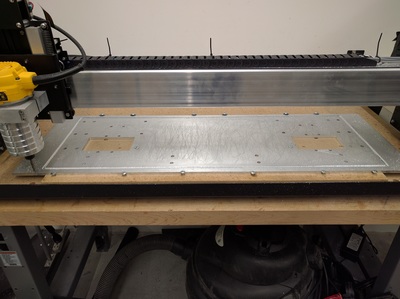

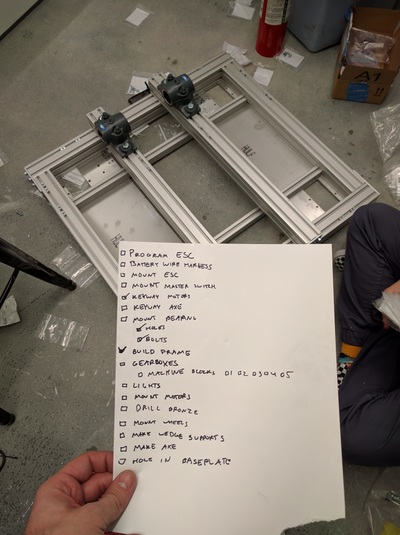

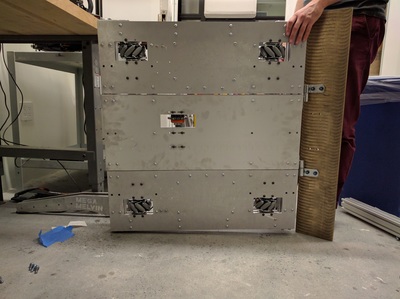

We're going to talk a bit about practice, testing, and fun. Isn't fun the whole point of this hobby? In the last post we talked about brushless vs brushed, modern vs old, etc. I'm going to cut right to the chase: Castle 2028 Motors and Mamba XLX ESCs are the future of this sport for anything over 30 lbs. Heck, maybe even for a crazy 30. Go buy them: Castle 2028 Motor Castle Mamba XLX This motor and controller combo can handle 7500 watt peak output for a few seconds. Pretty crazy. Ok, so let's backtrack a bit and get back to why these specifically are awesome. Originally I had intended to build a test platform and grab some numbers. Things like a torque/amperage graph, stall torque, that sort of stuff. Then a fun thing happened, my test platform lit on fire. It wasn't the fault of anything other than some faulty capacitors. It happens. But that was kind of boring. I end up with a fire and I didn't even have a robot yet! Then I found an equation online I probably should have known about to begin with. Kt * Kv = 1352 (torque is oz-in/a) This is super useful! Because I know the Kv, this lets me figure out the torque of the Castle 2028 at whatever amperage I want. Super useful for figuring things out like "can this motor push my heavyweight?". This coincided with me finding out about a HW Sportsman Class competition in Florida (Battles at Maker Faire), about a month out. Could I build a robot in a month? Sounds difficult... but also fun. And isn't that the whole point of a hobby, to have fun? Read on for a high-level post about how we built and fought Mega Melvin in a month: This competition would be the perfect spot to test out a new type of drivetrain I had been thinking about: sensorless brushless mecanum drive. At the voltage I wanted to run this would be a 30 hp drive system. This would be insanely powerful, and let the robot drive sideways with crazy maneuverability ( If you want to read about mecanum drive, check out the wiki ). It was also generally considered "insane" as brushless motors have a habit of not working well at all in the drive of heavy robots, in even normal settings. I could have built a platform on some wood and tested it in a parking lot, but I've done that with bots before only to have them blow up in the arena for who-knows-what reasons. Fighting real robots is also more fun than parking lots. Mega Melvin, first and foremost, was a test to see if we could get this working in an arena. If you're wondering: we did. Here is a fight vs Old Iron which shows the robot driving sideways without issue (the axe had other issues causing it to be quite anemic...): But at the time I was designing it, I had no idea if it would work or not, and no time to futz around. I had to get moving quickly and get parts on order. I ordered 5X castle motors and escs (1 for the weapon: an axe, because axes are cool) and then got to work on figuring out gearing. I'm going to spend the majority of this post talking about the drive system, and I'll do another post about the weapon soon (we're... working on some upgrades). So the thing about these motors is they are super high RPM. At 22V an 800KV motor has a no-load speed of about 17600 RPM. This is a lot higher than you'll see if you're running large scaled brushed motors, or outrunner brushless motors. But the important thing here is they are inrunner brushless motors. Inrunner vs outrunner... you can read about the differences on countless blogs. But other than RPM, inrunners are generally way more durable, which is a big deal for combat robots. So, what can we do this rpm thing? Banebots P80 gearboxes to the rescue! Banebots custom planetary gearboxes can be made out of entirely steel gears, with 3" long 1/2" steel output shafts, and 85 ft-lbs max torque. Awesome sauce. But what ratio do I need? I wanted to make a low robot, and had found some 4" wheels I liked. With 17600 RPM max, I could get around 13mph with 16-1 gearboxes. This seemed pretty decent for a first try. But what about torque? That's where this lovely equation comes in: Kt * Kv = 1352 I know Kv of the motor is 800. So Kt must be 1352/800 = 1.69 oz*in/amp. With a 16-1 gearbox, this multiplies the torque by 16, super handy because it just converts the torque to 1.69 lb*in/amp. If we assume perfect traction (ha!) then with 4 inch tires I need 110 lb*in torque per wheel to spin my tires at a standstill (220 lbs robot, 55 lbs per wheel, 2" lever arm made by the radius of the wheel). So divide 110/1.69 and it only takes 65 amps to spin my tires. With another robot on top we're still only at 130 amps. Well under the approximately 200 amps continuous the controllers can handle, and once you take into account the fact that the wheels will not have perfect traction and actually slip a lot, we're way under the limit. We're also way under the 85 ft-lbs max torque of the gearbox (we're only at 18 ft*lbs, even with another bot on top). Great! I might even be able to move up to 8S at some point if I want. So, I bought 5X of these: P80 16-1 With extra long shafts and steel ring gear. They're great, except that they are not designed to mount Castle 2028 motors to them. Compared to the motors these were meant to mount, the Castle had the same diameter shaft... but everything else was different. Mounting holes, shaft length, keyed vs flat. Luckily at work we just got a nice new desktop mill (A Carbide Nomad 883 if your'e wondering). This let me machine the mounting plate down to an appropriate thickness, and add the correct mounting holes. In the meantime I had to build a frame. Designing and building a frame is time consuming business. I had no time. But thanks to the magic of 80/20 I was able to make a frame pretty quickly. I usually wouldn't build a frame out of 80/20. It's inefficient on weight, and space, and cost. But there were no spinners in the competition we were going to, so I had less to worry about. Using our other new tool at work, a Shapeoko 3, I made some top/bottom armor and we started bolting the whole thing together. Yes, you can mill aluminum on a $1500 Shapeoko 3. I was stunned. This is a huge development for bot builders. I always have grand plans starting a new robot. "This time I won't be building it in the pits!" I say. "This time I won't be match drilling with printouts! Or hand drilling mounting holes at the last minute!" Sigh. But The frame was getting there, if late. That list of to-dos was one week before the competition. The test fit of the batteries was only a few days prior. And then I realized I had to assemble the gearboxes. And I also remembered that my motor shafts weren't keyed... Do I recommend grinding keyways into your shafts 2 days before a competition? No. The heat is an issue, the precision is an issue, everything is an issue. But... it worked, so... After getting those assembled and in the robot... it was time to leave. Our shop was located in Brooklyn, at my job at frog design. The competition was in Orlando, over 1000 miles away. We had to leave a bit earlier than we would have liked... You may notice the lack of wiring inside the robot. Although our motors are brushless, sadly they are not wireless. I swear, one day, I will design and build a robot that does not leave me soldering together a wiring harness the night before the event in a hotel bathroom. That lovely solder joint on the left, and the others like it, actually held up. That one on the right, the last one I soldered up... you may notice that the black wire goes into the positive side of the connector. This blew up 2 batteries and a controller. That's a $400 error. Don't solder while tired folks!

The other benefit of these castle motors and controllers is that they are designed for (huge) R/C cars. Which means if you're near a really good hobby shop, they'll have some in stock. We actually found a replacement controller within 10 miles of the event. Score! But after blowing up those batteries, the axe was running at a way lower voltage than we had intended. Boo. But! We got it all together. And it worked! And we got third place! We got the drive running at about 11am on event day. You've already seen the video, and you're probably wondering why it looked like we were running slower than 13mph. This is a good question! Let's spend the last part of this update talking about the Mamba XLX ESC and what we learned. First off, nothing got hot in our fights. Nothing even got WARM. Not the motors, not the batteries, not the ESCs. I was actually running without fans on the ESCs due to running out of ports to plug them into, and still nothing got remotely warm. These are car controllers, which is awesome and very important because that means they're designed to accelerate loads from a dead stop. Plane and boat controllers are bad, because those loads increase as RPM increases: not what we need for combat robotics. We need high torque at low RPM and that's what car controllers deliver. There is a lot of fancy programming inside these boxes that controls this. The biggest change with these controllers though is that they have what's called "Torque Limiting" built in to them. This is a vague setting that goes from 0.2 - 10, with 10 being the maximum torque. If you're not looking closely you might not even realize the controller has it, but it's possibly the greatest feature. Even those HUGE MGM Compro controllers can't do that. For this event we ran everything at 2.0, because I didn't want stuff to smoke. This effectively slowed us down. But this is good, because it means it works. Even in our axe with sudden reversing/stall cases: it worked. Torque Limiting is HUGE, because torque = amps. This means the controllers will keep themselves, and the motors, and the batteries, from blowing up. "Smoking" from a stalled motor will be a thing of the past. Set your torque limit right, and you can bash the crap out of your bot without worrying the electronics are going to fry. And it actually, really works. Your other bet is to oversize your controller to handle brief stall conditions, and other sudden instances that can peak torque/amperage. This results in a huge, expensive controller, that only matters for a split second every match or two. Or, get a controller that just limits those instances. I like the latter. That said I'd probably set the torque limit to at least 5 going forward... One more important note here: There are very fancy 20A battery-elimination-circuits built into these ESCs. These are so that if you plug one into your receiver, your receiver won't need a battery. This is great, but you can't plug TWO BECs into your receiver, or bad stuff can happen. Our robot had 5. To disable the BEC you need to cut the red wire leading from both the AUX and REC cables on the ESC... but if you do that then you can't connect the controller to your PC to change settings. Annoying. So don't cut it. Some people put in switches... but that's also annoying. Just buy some servo extension cables and remove the red wire: Servo extension cables By doing this you can just unplug the ESC from the extension cable, and into your PC, and vice versa. You can then just leave one plugged into your receiver with the red wire to power everything. Anyway, a lot more stuff went into this bot, obviously, than what's shown here. This is just a high-level overview of the drive platform performance. I'll use future posts to dive into things like mixing, mecanum wheel performance, weapon performance, batteries, better event reports, stories about last minute trips to Lowes, how to make really cool team jerseys, etc. One last note: I don't work for, nor am I sponsored by, Castle, or any other product linked here. If I ever am, I'll tell you. That said, my links are Amazon Affiliate links, and I get a small percentage of any product you buy after clicking them. So, thanks for supporting us if you buy through those links :)

4 Comments

11/8/2016 08:52:53 am

We went to "Battles at Maker Faire" which is in Florida, and holds only non-spinner weapon HWs. There was a decent showing: 7 people brought HWs though only 6 worked. It's more of an "exhibition" style event where you just want to have fun. Nobody had weapons that would be really damaging (I'll probably keep the axe toned down next year to keep in the theme of the event). Supposedly, they will be having this event again next year, with another event in between. So, 2 events every year for sportsman style HWs on the east coast. Pretty cool!

Reply

Leave a Reply. |

Bots FCBrooklyn's Professional Robotics Team & home of the Battlebots Emulsifier & Shatter! Archives

March 2022

Categories |

RSS Feed

RSS Feed