|

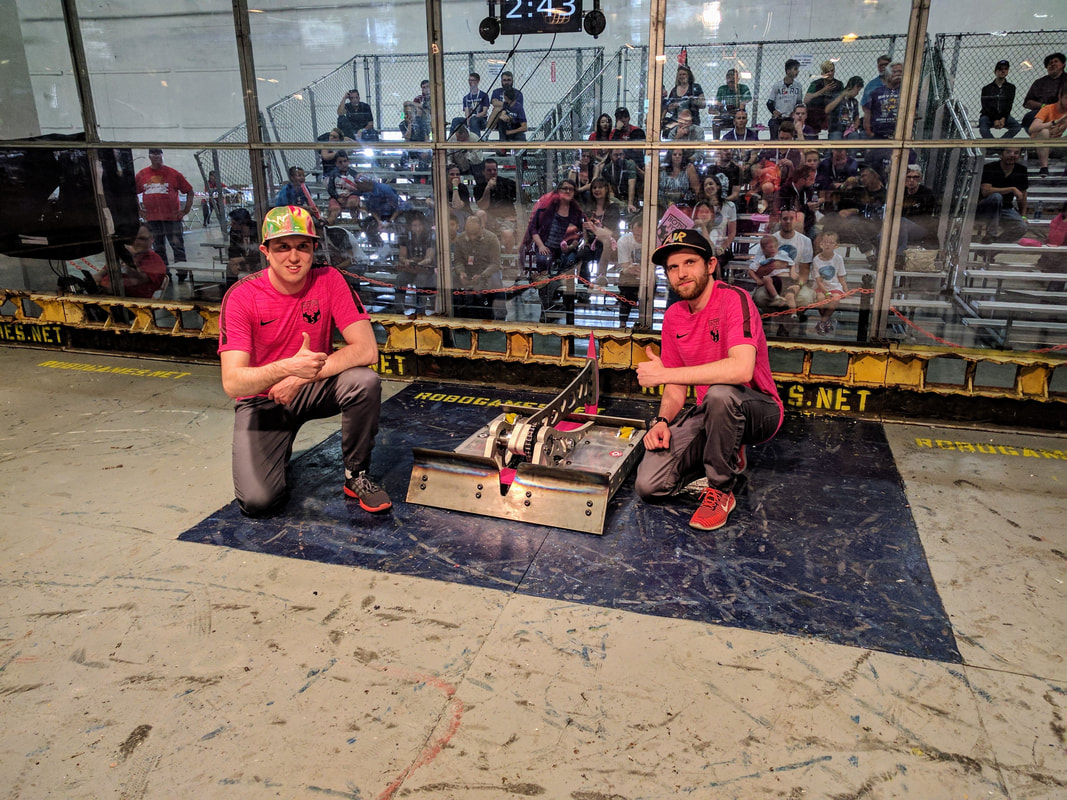

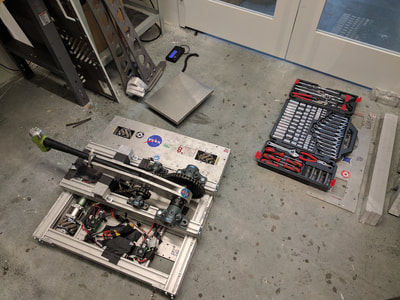

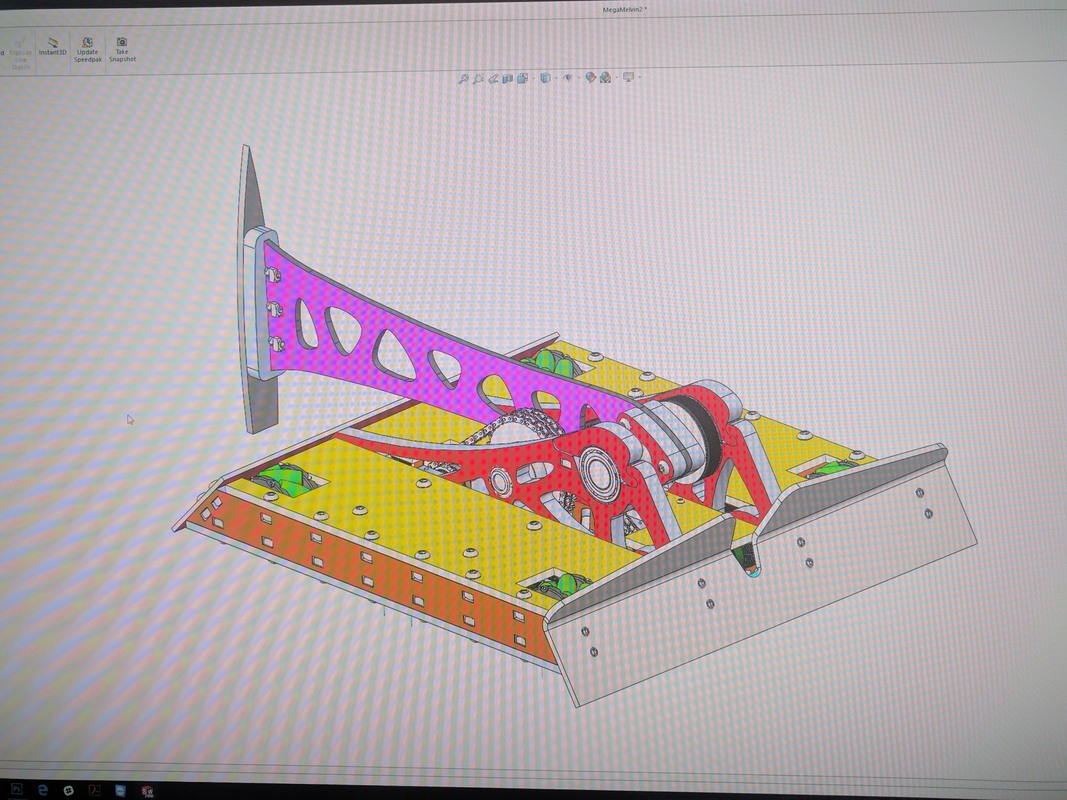

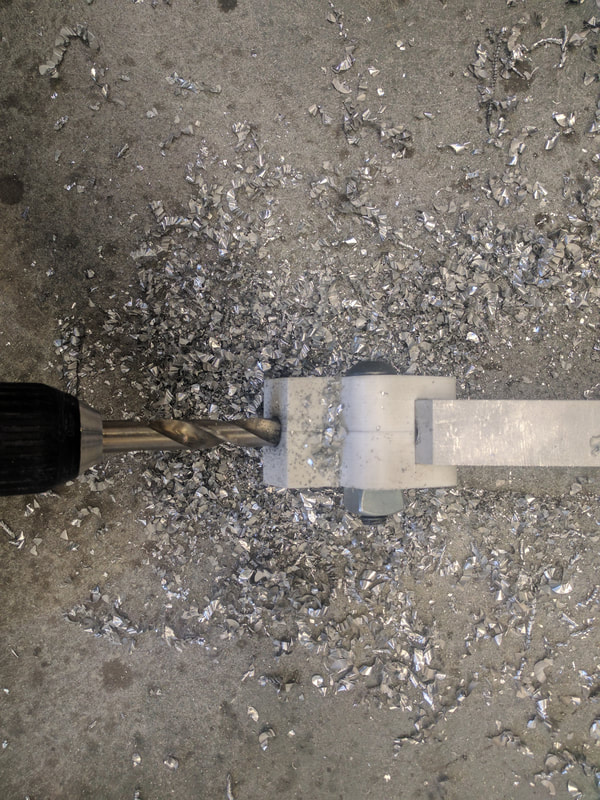

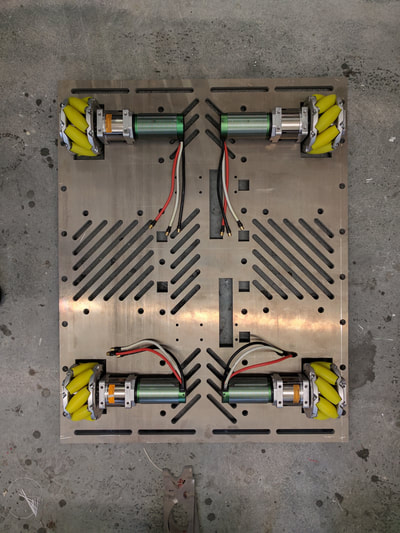

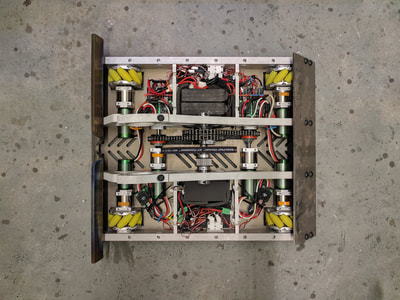

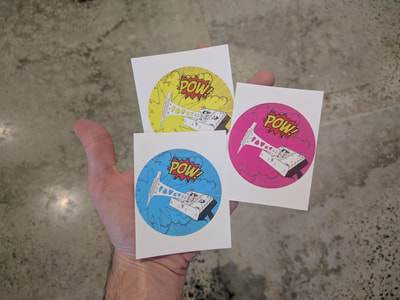

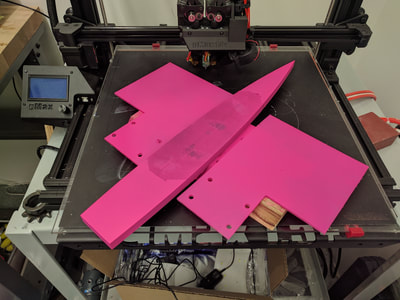

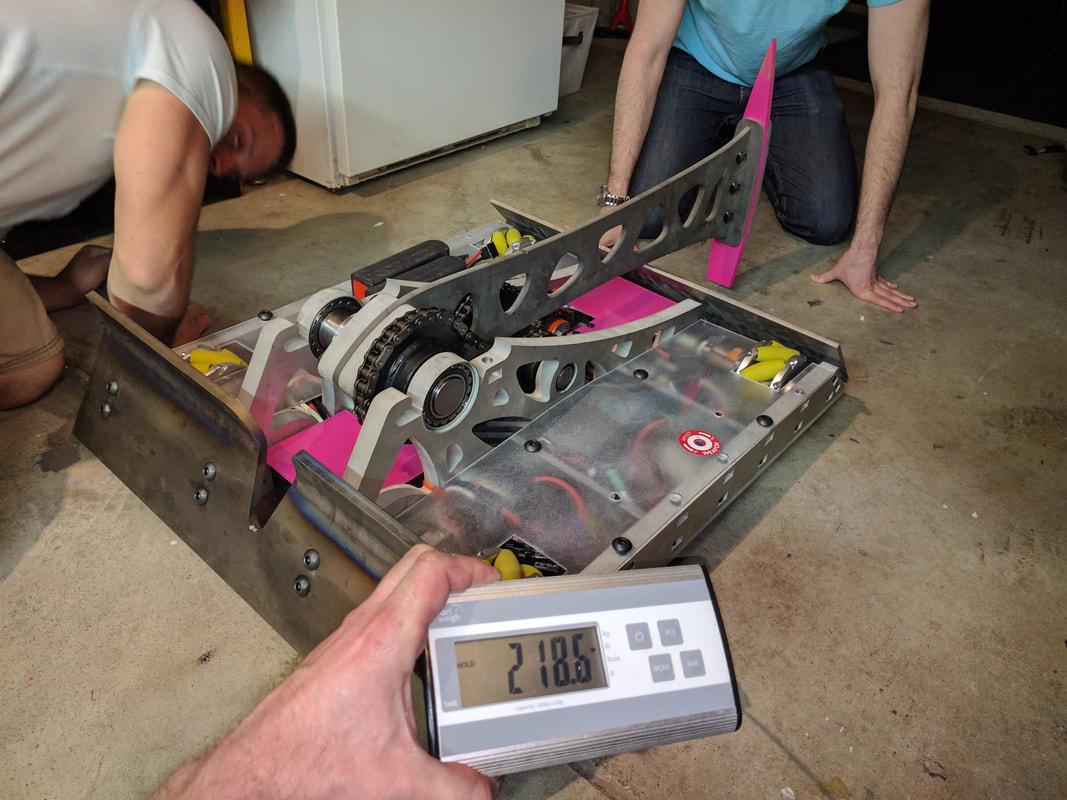

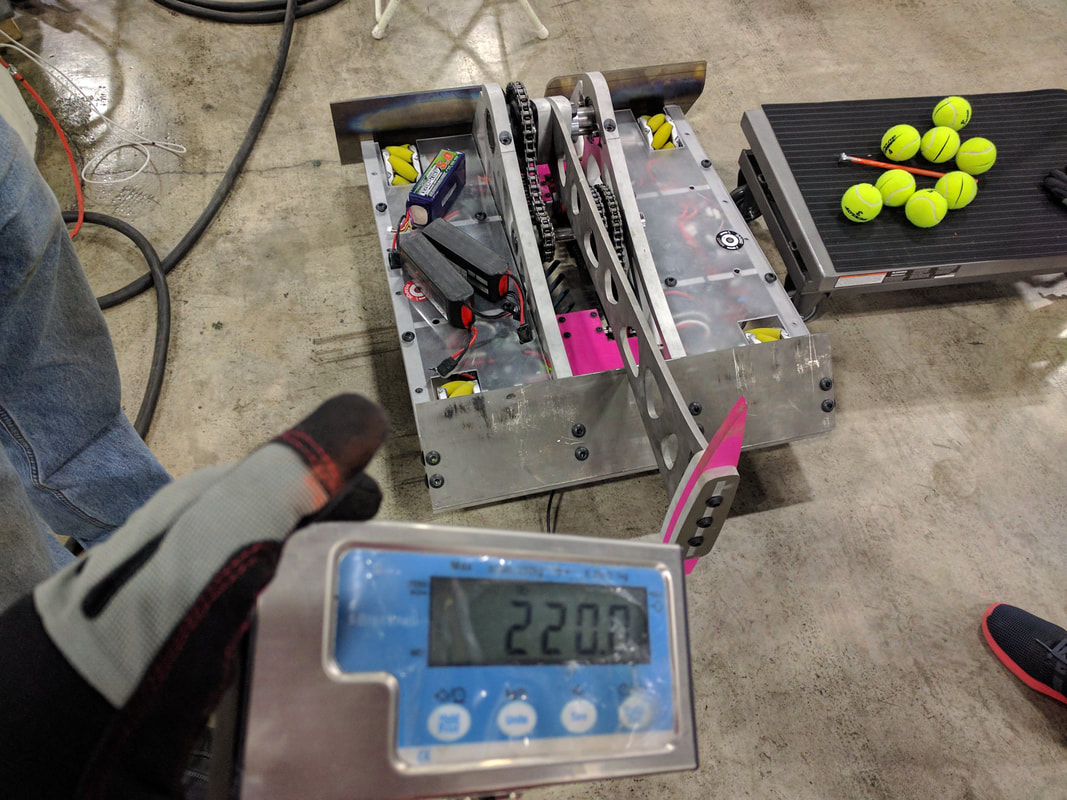

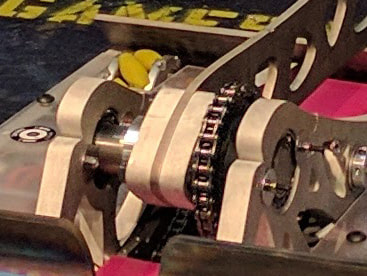

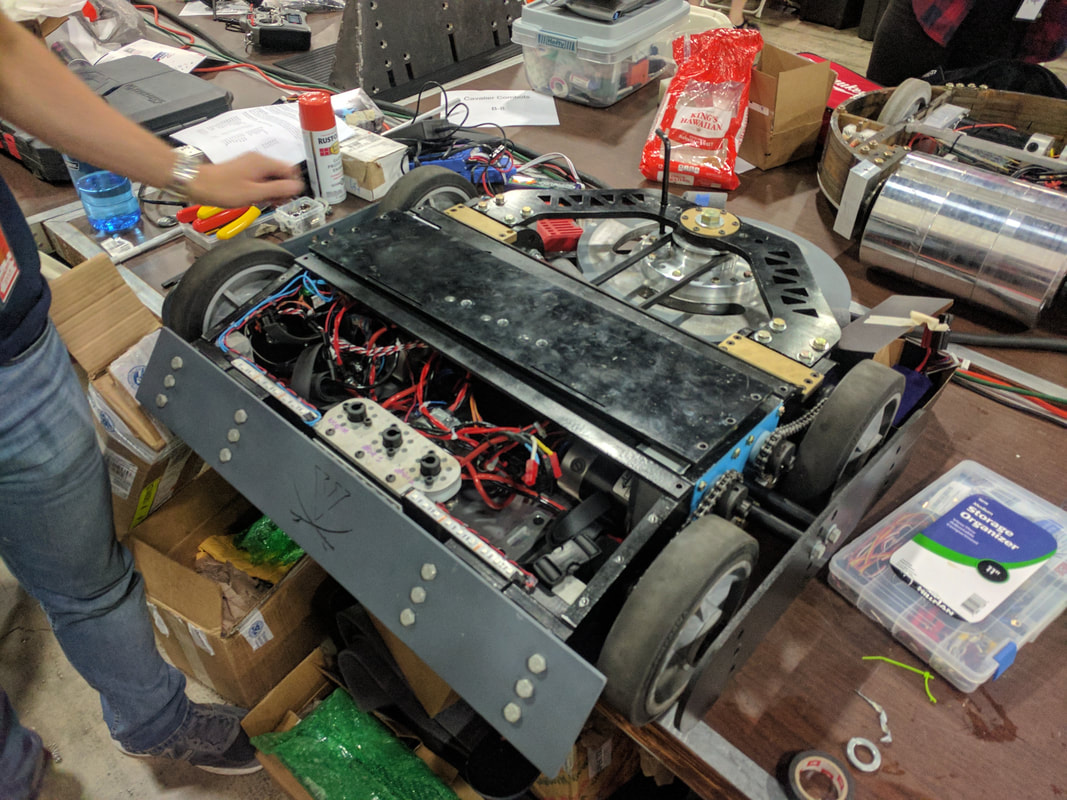

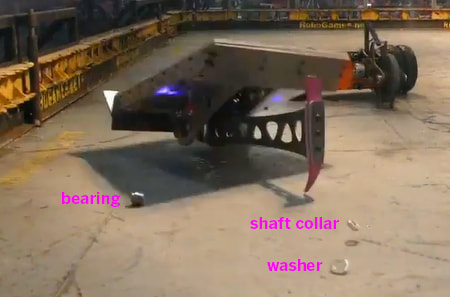

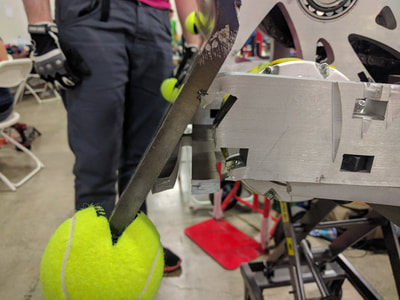

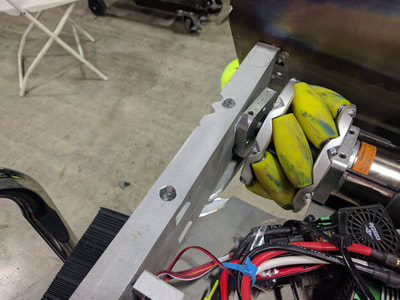

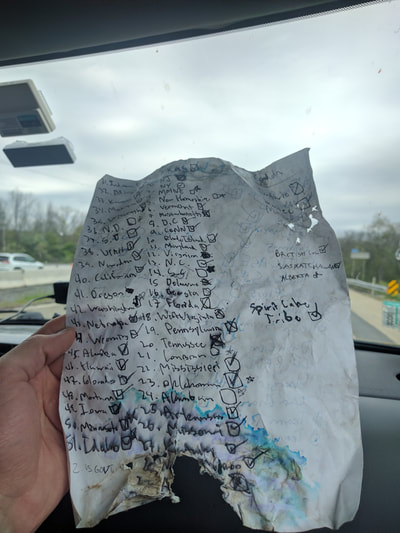

Well it's almost the end of the year, so I should probably do an update about Robogames! When I last left off we had a pile of parts. As you can see above, we managed to put them all together! Let's talk about how after the break. First things first, we need the motors/gearboxes/wire-harness from Mega Melvin V1. Thus there was the unenjoyable necessity of cannibalizing our first ever HW robot for parts. :( Pour out a 40 for my homie. With that sad task done, the next thing to do once we got the parts back from the waterjet (love em: http://www.waterjet.nyc/ ) was slap them haphazardly together and see how it would all look: This is my favorite part of the build process because it's the easiest part. You get to feel like you built a robot without doing much! Ok, take a deep breath, and let's get to the real work. You may remember our original design had a large V shaped plow in front, to deflect spinners. This turned out to be way too heavy/costly/annoying to make. So I didn't make it. When I put all the parts down I immediately realized the front wedge was too small and had flashbacks to Beta vs Tombstone and how Beta's supports got mangled as the spinner went up the plow. Sometimes you just need to see it in the flesh to really 'see' it. I found a piece of thicker surplus titanium that fit in my weight estimates and hastily drew up something and sent it off to the waterjet guys to get made (at this point I think we only had about a week til we had to leave for Robogames...) Yes I took a photo of my screen. Deal with it. So back to assembling the robot. We had the parts waterjet, but that's it. So we had to drill a LOT of holes in the frame to actually assemble it. We used modified T-slots to hold nuts for all the bolts since I hate threaded holes. Instead of a full "T" slot though, we drilled into a captive rectangle hole which held the nuts. This was stronger than a normal T but a real pain to do. I sent out RFQ's to a lot of places to make these holes. I either got ignored, told it would be $5000, or told they didn't have the machinery to do it. HW parts are big and shipping them all over the country is difficult... and NYC is expensive for machining. Who knew? So, 3D printed jigs it is. Yay holes. Here's a closeup of how we did it. We used 1/2" ID copper tubing to keep the drill bit and chips from melting the 3D print (learned that the hard way) and the print actually grips into the rectangle hole for placement. It took us 2 straight 8-hour days to do all the drilling. Probably should have used the drill press for the straight holes... but you live you learn. With the frame members drilled, let's put it all together! Now isn't that something! And with it all bolted together, we can drive it around! You may have caught it earlier, but here's our 1/2" thick grade 5 titanium plow, on the bot only a few days before we left on our road trip. They had to heat it up and bend it one half at a time, because the press stalled trying to bend the whole thing. Personally I love the scorch marks. Now, the only piece I didn't have waterjet was our main axe shaft... because you can't waterjet a shaft. It's a stepped piece of 2" thick titanium... because steel was way too heavy. It's 45mm on the outside to fit into our spherical "rock crusher" bearings, but 2" on the inside because the chain is all in imperial sizes. Yay mixing units. Our teammate Matt had machined the shaft, but he was in Ohio. When it was finished, there was only a week before we left from Brooklyn. If the shaft was lost in shipping, we couldn't finish the robot. So we didn't ship the shaft, we decided to pick it up on the way to California (oh, btw, we drove from Brooklyn to San Francisco...) So, when we left, the robot looked like this: We had our fingers crossed that the shaft would fit and everything was to spec, because we had very little time on the trip itself if anything went wrong. With the small amount of time we had before leaving. We painted things, made some swag, and new jerseys. Gotta have swag. Also you may have noticed the extremely thin top armor. That's 1/8" thick polycarbonate... because it turned out that awesome plow was a bit heavier than I had hoped. But who cares, we're the only hammer in Robogames... and off to Ohio! We arrived later than we wanted, I think about 8pm, and got to work. Of course it didn't fit at first, but eventually it fit after grinding something. I'm actually not even sure what it was, but I spent a lot of time grinding stuff and hammering things. You know how it goes. O.M.G. guys... is that 2 whole pounds under weight!!?! What a miracle! let's go test it to see if it works: Well, crap. That's carbon fiber "Polychain"... it's supposed to be just as strong as chain of equal width, but way lighter (and more expensive). Lies! Instantly snapped. What a bunch of crap. That's what I get for using a belt! New team slogan: Belts Blow Anyway, I brought chain as a backup because I expected this to happen, so lets go back and hammer/smash things some more and put the chain on: Holy crap! The chain only weighed 0.7 pounds? That's impossible! The robot must be stuck on something. How is this... oh, we left off the axle clamps. We ended up sitting at exactly 220 (220 is the limit for the weightclass) on the scale, but I don't have a photo of that because it was around midnight but this point and we were quite tired. Never good to be that close because who knows how accurate my/their scale will be. Anyway, let's go test: Yay! It works! And it's awesome! Sure, the bearing clamps had a habit of working themselves out sideways but... whatever. It works! Let's get it in the car, get going, and worry about that later! Like a glove! And off we drove for a few days. We did a quick stop off at a home depot to buy some "elevator bots" and big washers to hold our axle clamps from spinning, and then stuck the thing on the Robogames scale. After some considered bolt-removal, we landed at exactly 220.0. We were actually one of the first HW teams through and it was a huge relief. In case you're wondering what elevator bolts are, they're basically a bolt without a head, and instead a big wide flat disc. I use that disc, and a big washer on the other end, to hold the bearings/clamps from shifting sideways. It was a super last-minute solution, but it's worked extremely well for us and I haven't bothered changing it. Sorry for the poor photo: The bot is assembled. The brackets are drawn up... and now it's time to fight... or at least time to worry about the fight while we wait hours until the fight actually happens. In the first round we drew our pit neighbors, The University of Virginia, and this cool horizontal disc spinner. I was really excited for the fight, because it wasn't a vertical disc spinner and I really didn't want to fight a vertical disc spinner. Yay. At this point, if you've seen Robogames, you're saying to yourself "Adam, I never saw that fight! That never happened!" and that's true. We never got to fight The University of Virginia because they redid the brackets. I don't know why but every competition we go to they redo the brackets. It's a tradition at this point. So in the new bracket we got... Polar Vortex. A vertical disc spinner. yay. The cool thing about being the only hammer is that everyone was scrambling to come up with armor and defenses only to use against us. We even had Ray Billings say he didn't want to fight us. Now that's an accomplishment. You can see above Polar Vortex's special shock mounted top armor. Here's the fight: Bah! Very quick, very annoying, didn't even get to test out that amor! Also annoying was the Robogames Twitch live stream cut out for our fight, and our fight only! Too much hype I suppose. So let's talk about what happened here. 1. I didn't have nearly enough driving practice, ha. You can see me drifting all over trying to over correct. 2. I got over aggressive. I tried to push Polar Vortex into the wall but I missed. As we missed we shot the hammer off and when we shoot the hammer we hop in the air. At exactly that moment, Polar Vortex turned and hit us in the side. Perfect hit. 3. If you look closely at the moment just before the hit, you can see that as we hop into the air, we actually hit Polar Vortex's motor with the front of our wedge, and a piece goes flying off. This is apparently a guard from his weapon motor, and after the fight Fuzzy (builder of Polar Vortex) told us that we had busted his motor. If only we could have kept running. 4. When we went flying, lots of bits came off us. These were the shaft collars that held the bearings in place on our mid stage chain for the hammer. When the bearings came out, the chain got too lose, and we couldn't self right as the chain slipped. Blargh. The announcers thought the axe was too weak, but that's not the case. You may be asking why the shaft collar came off. This is because the shaft was too short, and didn't leave enough room for the shaft collar to grip. Another casualty of time. 5. The axe bent. This happened because although it was S7 tool steel... I didn't have time to harden it. Oops. We flipped it for the next fight. So, lessons learned. Let's take a look at the damage: Ouch. Let's sum up the damage here: 1. The gearbox axle is toast. Was a bit of a pain to get the wheel off but we did it. 2. Side is destroyed. That's 1" thick 6061 aluminum and look how bent it is! 3. The corner of our baseplate is gone. That's 1/2" thick 7075 aluminum. Interesting shear pattern at least. 4. The ESC closest to the hit stopped working. Total cost of hit approximately $1,500... but we got some Team Toad T-Shirts out of the deal so I guess it's even. Polar Vortex got to fight Magabyte after us... maybe it was better to lose because, well, ouch. Anyway, after a few hours of frantic repairs we got a new motor/wheel/side into Mega Melvin. Time for fight number two, this time vs well armored wedge Megalodon. The Battle of the Megas! :( This fight was annoying all around. Summary: 1. We lost drive after being hit into the wall and fun fact, so did Megalodon (that's why they couldn't move, not that we were too heavy or something, they just couldn't move at all). 2. Our drive did not come back, but Megalodon's did. We started firing the hammer trying to get our drive working again. We thought maybe something had come lose. This did not work. 3. During the time we were firing our hammer, Megalodon didn't move. We assumed this was because they were just waiting for us to move. This was not the case, their drive had broken again. It started to work right after we were counted out. So, blargh, if only we had kept running once again! After the fight we found our culprit: That's a $10 battery eliminator for our drive receiver. We have 4 ESCs on drive and I had heard that running 4 BECs on one receiver is bad, so instead I just got a separate one to use instead of the ones built into the ESCs. Somehow in that hit, this thing shorted out and busted our drive receiver. 5 minutes in the pits and I had it running again like new. And that's it for Mega Melvin at Robogames 2017 :( We had wanted to do an exhibition match but it was cancelled at the last minute due to fears we would damage the arena. Why is that? Well... It may look like we just chipped paint, but the floor is actually very dented. We got to watch a lot of fights after we were knocked out of the tournament, and 2 other robots actually got stuck in the dent we made and counted out. So I think that means we went 2-2 for the tournament right?

Overall it sucks to lose, but the bot is still mostly in one piece so that's nice. I leave you with some ridiculous selfies and other photos from our cross country road trip. Next time we talk about... CHINA!

6 Comments

6/7/2020 04:59:34 pm

I love these robogames so much, dude. I do not believe that there is anything that is greater that them. I have a lot of free time on my hands, which is why I was able to do this much. I already know that it is going to take a while before I become better at what I am trying to do. I know that it will take a long time before I can understand why other people have no love for them.

Reply

6/7/2023 03:29:47 am

For instance, will expertly get together your things, load them into their trucks, drive them to your new home and dump everything in the right rooms in the house. A few property holders, be that as it may.

Reply

6/7/2023 04:13:55 am

It educates individuals on setting appropriate stop-loss levels, determining position sizes, and implementing proper risk-reward ratios to ensure long term profitability. By investing time and effort in forex education.

Reply

6/7/2023 04:40:19 am

Weather conditions is one more solid consider concluding the sort of shingles unforgiving and serious weather patterns require harder and more grounded rooftops. These are thusly more costly.

Reply

6/7/2023 05:19:05 am

The durable goals of the bed and breakfast have been designed for the satisfaction of people. The stance of the is looked for the team work is filed for the turns. Joy is met for the approval of the joy for the terms for the citizens.

Reply

Leave a Reply. |

Bots FCBrooklyn's Professional Robotics Team & home of the Battlebots Emulsifier & Shatter! Archives

March 2022

Categories |

RSS Feed

RSS Feed