|

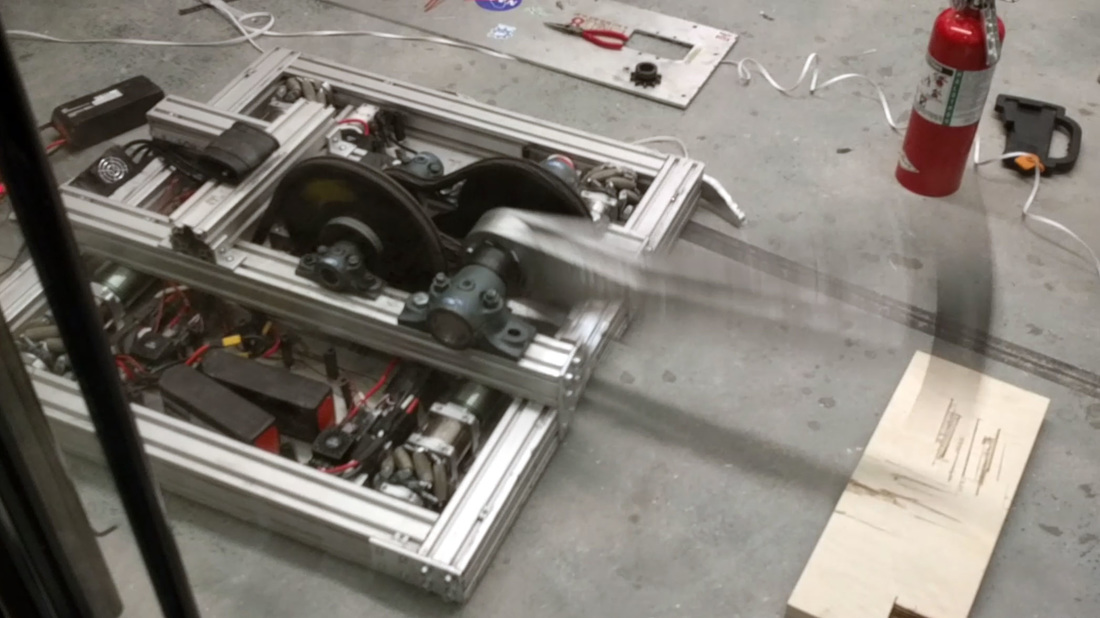

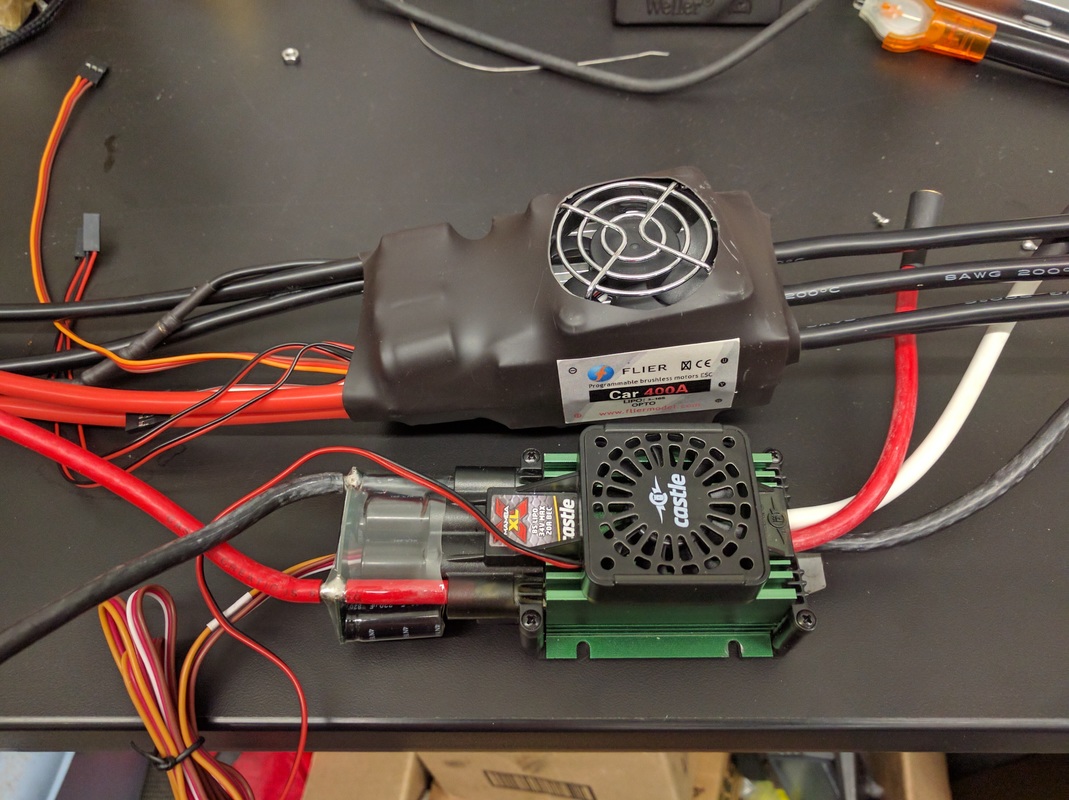

Building a brushless powered axe is a bit tricky, as is anything brushless at these scales. This post is an update on how we're attempting to build the most insane axe robot ever, and we'll go over our progress from our slow axe at Maker Faire to our current axe, which is pretty scary. Hit the jump for videos and math! I'm not going to dive into brushed vs brushless motors here, plenty of people have. The important thing to know is that brushed motors use a mechanical system to properly switch power around internally, whereas brushless motors rely on the speed controller to properly switch everything as the motor is spinning. Sort of like a carburetor vs fuel injection in a combustion engine. Brushless motors work great once they spin up, but because of the electronic switching can have issues at low speed, this is called "cogging" and can result in the motor just stopping in place instead of spinning. Short, rapid back and forth movement is the worst thing for brushless motors to handle, and is exactly what you need in an axe. So, how did we overcome this? From the last article you probably saw our axe going really slow. If not, check out this rumble (fight starts around 3 minutes in): I had done some calculations for the axe so that the force at the tip would be about 200 lbs, which was a lot of gearing. Everyone's first thought was just that I geared it to0 slow. I had actually geared it so that it should have fired in around 1/4 of a second. This is clearly not what was happening, so lets dive into the gearing calculations a bit: I used our torque number from last time: 1.69 lb*in/amp coming out of the gearbox. I combined this with a quote from Castle's website: These “go big” motors can easily run in the 10 horsepower range* *Burst power output for durations typical of vehicle acceleration. I wanted to run the axe at 8S, the max voltage that the Castle ESC could handle. 8S is about 30V, and 10HP is about 7500 watts. Watts = amps * voltage so I know that the ESC can handle about 250 amps for a few seconds. Perfect, since it only takes a fraction of a second to fire the axe. So, I have a 250 amp max, which means that coming out of the gearbox I have about 35 ft lbs max torque. The axe is two feet long which means I want about 400 ft lbs of torque on the arm. 400/35 means I want to put an extra 11.4-1 gearing onto my axe for a total of around 183-1 gearing as an optimum. I ended up at 205-1 based on available sprocket sizes. I also put in a slip clutch on the gearbox shaft, which limited the torque to 35 ft*lbs so that I could never go over 250 amps from the motor. At those numbers I should have had an RPM at the axe of around 120, which would mean the axe firing in around 0.25s: that's quite fast! But as you watch the video you can see I wasn't close to that: it actually took a full second to fire the axe. Why? First off I was running at 6S since I had blown up my 8S batteries. That's an immediate loss of 25% speed but it should have still been around 90RPM, or 1/3 second per fire. So after the competition when I had some free time I went in and checked the Castle ESC logs. As on the drive I had set torque limiting to 2 out of 10, and I had startup torque set to "low." I switched the torque limiting all the way up to the max (since I have a mechanical torque limiter in place) and set startup torque to high. After doing that I immediately doubled the axe speed: So now we're at 0.5s firing time, which is about 60 or so RPM. Still slower than it should be, but much much better. Speed here is quite possibly limited by friction in the geartrain which consists of split bushings mounted on 80-20... it's not very smooth. The axe has a ton of torque at this point. Enough to be used as a lifter, and way more than enough to self right. So I ordered some new gearing to bring the force at the axe tip down to 150 lbs. Still more than enough to self right, and you can see the robot lifting itself at the start by firing the axe into the ground: Now we're getting somewhere. At this point we're running at about 90 rpm or 0.33s per fire. But it is still not super impressive. Acceleration is instant and although or axe firing time is very close to a robot like Beta, it doesn't feel like our speed is anywhere near them. They start off slower and accelerate to a much higher velocity by the end of their swing. At this point I only had 6S batteries, but I did have a nice wiring rig to put them together into 12S, too high for a Castle Mamba XLX. So I ordered a new ESC straight from China. This thing is a beast. Double 8 gauge input wires, 400A at 16S max. It's big, it's heavy. You'll see it marketed under a lot of brand names, including Alien Power Systems and Kershaw Designs, but it's cheaper if you just go through Ali Express. Anyway, wow. But it doesn't have nearly the same amount of programming options as the Castle. When I hooked it up to the motor it was LOUD, clearly not running as efficiently as the Castle. Not only that, the thing ejected smoke like a fog machine, and the caps got really hot. I've never seen anything like it. Yet somehow it still functioned even after pumping out a cloud of toxic fumes into my workshop, and eventually cooled down. Now it's starting to get a bit scary, but you can see some issues popping up. One of the swings stops halfway through. In a lot of other tests the axe would just drastically slow down in the middle of the swing: this is cogging. Another interesting thing here is the axe is starting off much slower than previously. Even at max settings with double the voltage this controller can't hit the same initial torque as the Castle Mamba XLX, and yet it's still cogging like mad. Sheesh. So this is no good. Perhaps it's related to all the magic smoke it shot out in the beginning, who knows. Timing wise, we're still at around 0.33s per swing, but clearly faster at the end of the swing than in the previous test.

All this stuff is good to know, but there is actually another interesting fact here. As we went over before, the motor is rated at 7500 watts max. I'm running here at 12S, or around 50V. At 50V my max amperage is only 150 amps. So even though I'm running the same gearing, I can't pump more than 150 amps into the motor without exceeding its rating (which means melting things inside the motor, or going past the magnets' heat ratings, which is bad). At 150 amps I only have 90 lbs of force at the axe tip, which is not going to be enough to self right (I want at least half the weight of the robot at the tip). If all I wanted to do was trade torque for speed I could have just changed the gearing... so in the end the controller didn't work, and I couldn't get the most out of it anyway without blowing up the motor. So how did we avoid cogging? Because the Castle ESC has better internal logic. It runs the motors much more quietly and pulls way more initial torque out, even running at lower voltages. So basically, once again, Castle is awesome. Go buy them, and not random ESCs from aliexpress: Castle 2028 Motor Castle Mamba XLX So where do we go from here? Well, my new 8S batteries are finally getting here next week. I'm going to plop them in with the Castle ESC and this should get a speed similar to the 12S system since we'll have a lot more startup torque this way. Hopefully running at 8S won't have any cogging issues on the Castle, we'll see. I'm also going to look into switching even faster gearing into it. Since this is a test platform I want to keep pushing it. Finally, the revised Mega Melvin design is going to have two motors powering the arm, for extra torque. I won't be able to test that for months though, when the new frame is ready. Eventually we're looking to have enough power to use a 3ft long axe (1 ft longer than currently shown) that can still have enough torque to self right. Not only that though, we're looking into the ability to change it out for a 2ft flipper arm with enough torque to launch other robots. Brushless launcher? Why not.

5 Comments

Hurtz

11/20/2016 03:52:15 pm

With beta the onboard micro uses a fixed time to control the power-on during fire, avoiding stalling the motor when it hits. When we hit the fire button is applies power (at the current power setting) for 300 msec. When we release the button it applies (lower) power for 300 msec. We have full manual control for self-righting.

Reply

BotsFC Adam

11/28/2016 09:37:05 am

Very cool! Our OTS brushless controllers do not seem to have that ability. Perhaps if I were to dive into the transmitter/receiver there might be something? Seems like sending a precisely timed signal would be a somewhat common need. At the moment all our firing is fully manual, and the only fail-safe is a torque limiter on the motor. However, this causes a lot of extra amperage to be wasted in the over-swing period.

Reply

Orcinus Revi

2/23/2019 07:29:13 pm

IIRC Beta also used a snail cam configuration so the motor torque perceived by the hammer is high at the beginning, yet when the ESC achieves the desired motor speed, it translates to a higher speed at the hammer, thus the acceleration keeps increasing instead of exponentially decaying. It's similar to the logic behind cars starting with low gear, and gradually increasing it

Reply

6/9/2023 03:46:45 am

All the types and kinds of wheelchairs are on display for the visitors of the website. The patterns of the wheelchairs for sale are ensured for all sales. The concession in the price is beneficial for the people who cannot buy the chair at full price due to fewer finances and resources.

Reply

6/9/2023 04:27:59 am

Yes, the approval of the services of the agency are valued and considered valid for future items. The push-ups of the digital marketing agency for startups are ensured for the youngsters. the fund is placed for the facts. Element iodine for the top of the guided element for the agency for the terms and goals for all people.

Reply

Leave a Reply. |

Bots FCBrooklyn's Professional Robotics Team & home of the Battlebots Emulsifier & Shatter! Archives

March 2022

Categories |

RSS Feed

RSS Feed